Torwell ABS Filament 1.75mm bakeng sa printa ea 3D le pene ea 3D

Likarolo tsa Sehlahisoa

| Letšoao | Torwell |

| Thepa | QiMei PA747 |

| Bophara | 1.75mm/2.85mm/3.0mm |

| Boima bo kahare | 1 Kg/spool; 250g/spool; 500g/spool; 3kg/spool; 5kg/spool; 10kg/spool |

| Boima bo felletseng | 1.2Kg/spool |

| Mamello | ± 0.03mm |

| Bolelele | 1.75mm(1kg) = 410m |

| Tikoloho ea Polokelo | E omme ebile e na le moea o kenang |

| Sebaka sa ho Omisa | 70˚C bakeng sa lihora tse 6 |

| Lisebelisoa tsa tšehetso | Sebelisa ka Torwell HIPS, Torwell PVA |

| Kamohelo ea Setifikeiti | CE, MSDS, Reach, FDA, TUV, SGS |

| E lumellana le | Makerbot, UP, Felix, Reprap, Ultimaker, End3, Creality3D, Raise3D, Prusa i3, Zortrax, XYZ Printing, Omni3D, Snapmaker, BIQU3D, BCN3D, MK3, AnkerMaker le liprinta life kapa life tse ling tsa FDM 3D |

Mebala e Mengata

'Mala o Fumanehang:

| 'Mala oa motheo | Bosweu, Botsho, Bofubedu, Boputsoa, Bosehla, Botala, Tlhaho, |

| 'Mala o mong | Silevera, Putsoa, Letlalo, Khauta, Pinki, Pherese, Lamunu, Khauta e mosehla, Lehong, Botala ba Keresemese, Boputsoa ba Galaxy, Boputsoa ba Leholimo, Bo bonaletsang |

| Letoto la khanya ea letsatsi | Bofubelu bo khanyang, Bosehla bo khanyang, Botala bo khanyang, Boputsoa bo khanyang |

| Letoto la khanya | Botala bo Bonang, Boputsoa bo Bonang |

| Letoto la ho fetola mebala | Botala bo boputsoa ho isa ho botala bo bosehla, Boputsoa ho isa ho bosweu, Pherese ho isa ho pinki, Bohlooho ho isa ho bosweu |

| Amohela 'Mala oa PMS oa Moreki |

Pontšo ea Mehlala

Sephutheloana

Filamente ea ABS ea moqolo oa 1kg e nang le desiccant ka har'a sephutheloana sa vaccum.

Sekotlolo se seng le se seng ka lebokoseng le le leng (lebokose la Torwell, lebokose le sa nke lehlakore, kapa lebokose le ikhethileng lea fumaneha).

Mabokose a 8 ka lebokose (boholo ba lebokose ke 44x44x19cm).

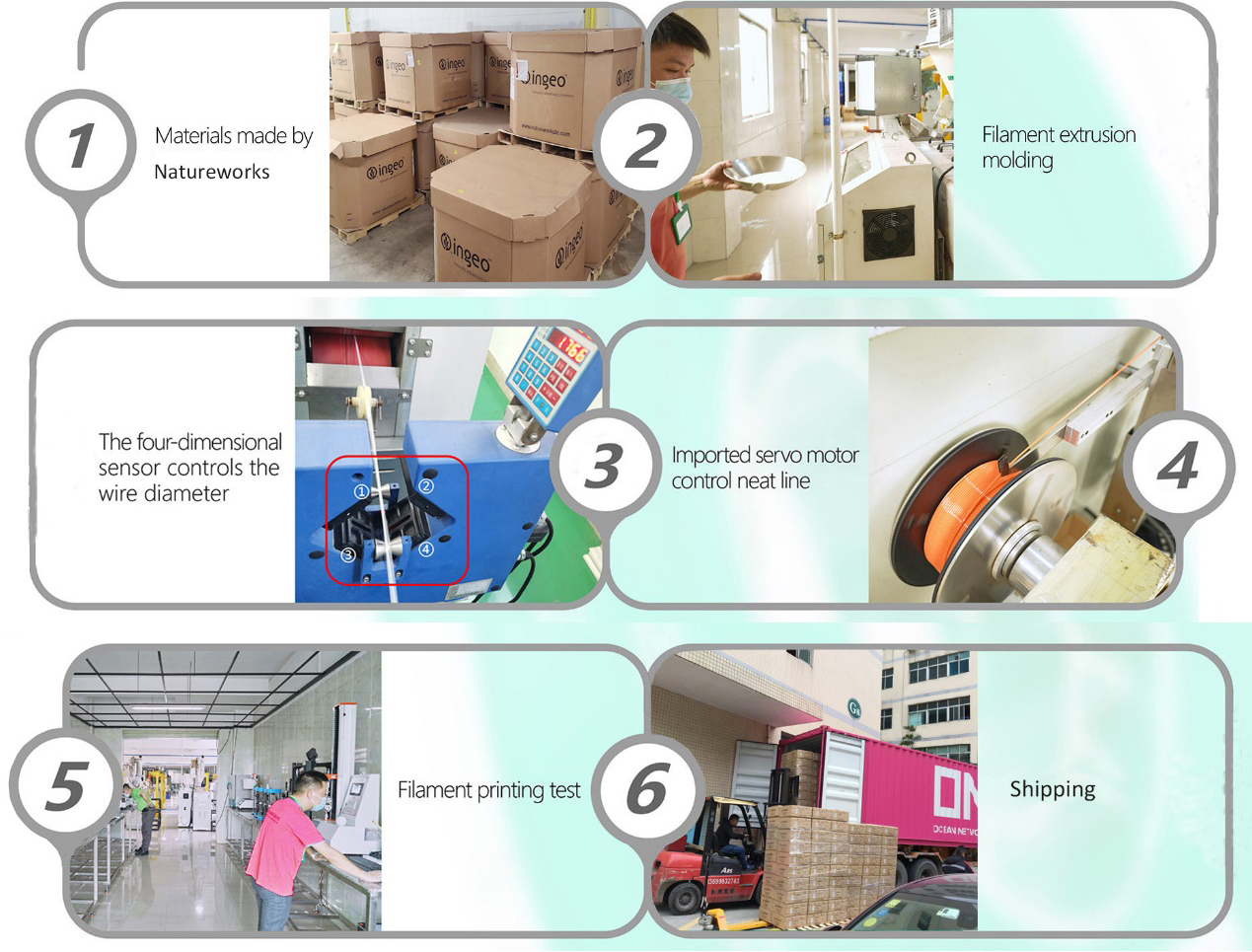

Setsi sa Feme

Tlhokomeliso ea Bohlokoa

Ka kopo fetisetsa khoele ka lesoba le tsitsitseng ho qoba ho kopana kamora ho e sebedisa. Khoele ea ABS ea 1.75 e hloka bethe e futhumatsang le sebaka se nepahetseng sa khatiso ho qoba ho sotha. Likarolo tse kholo li sekamela ho sotha liprintareng tsa lapeng 'me monko ha o hatisoa o matla ho feta ka PLA. Ho sebelisa raft kapa brim kapa ho fokotsa lebelo la lera la pele ho ka thusa ho qoba ho sotha.

LBH

Ke hobane'ng ha likhoele li sa khone ho khomarela betheng ea kaho?

1. Hlahloba boemo ba mocheso pele o printa, di-filament tsa ABS di na le mocheso o phahameng wa extrusion;

2. Hlahloba hore na bokaholimo ba poleiti bo se bo sebelisitsoe ka nako e telele, ho kgothaletswa ho bo nkela sebaka ka bo bocha ho netefatsa hore bo khomaretse ka matla lera la pele;

3. Haeba lera la pele le na le ho khomarela ho fokolang, ho kgothaletswa ho lokisa substrate e hatisitsoeng hape ho fokotsa sebaka se pakeng tsa nozzle le poleiti ya bokaholimo;

4. Haeba phello e se ntle, ho kgothaletswa ho leka ho hatisa moralo pele o printa.

| Botenya | 1.04 g/cm3 |

| Tekanyo ea Phallo ea Qhibilihang (g/10min) | 12 (220℃/10kg) |

| Mocheso oa ho sotha mocheso | 77℃, 0.45MPa |

| Matla a tšepe | 45 MPa |

| Ho Lelefatsa Nako ea Phomolo | 42% |

| Matla a ho Tenyetseha | 66.5MPa |

| Modulus ea ho Flexural | 1190 MPa |

| Matla a Tšusumetso ea IZOD | 30kJ/㎡ |

| Ho tšoarella | 8/10 |

| Ho ka hatisoa habonolo | 7/10 |

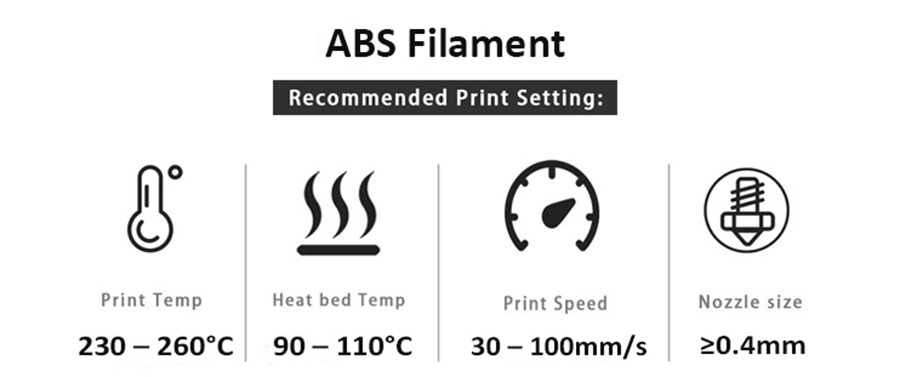

| Mocheso oa Extruder (℃) | 230 – 260℃Khothaletso ea 240℃ |

| Mocheso oa bethe (℃) | 90 – 110°C |

| Boholo ba Nozzle | ≥0.4mm |

| Lebelo la Fene | TLAASE bakeng sa boleng bo betere ba bokaholimo / TIMILO bakeng sa matla a betere |

| Lebelo la ho Hatisa | 30 – 100mm/s |

| Bethe e futhumetseng | E hlokahala |

| Libaka tse Khothaletsoang tsa Kaho | Khalase e nang le sekhomaretsi, Pampiri ea ho phuthela, Theipi e Putsoa, BuilTak, PEI |