Filamente ea TPU e tenyetsehang ea 95A 1.75mm bakeng sa khatiso ea 3D

Torwell FLEX TPU e na le bothata ba Shore ba 95 A, 'me e na le bolelele bo boholo ha e robeha ba 800%. Rua molemo ho mefuta e mengata ea lits'ebetso tse nang le Torwell FLEX TPU. Mohlala, li-handle tsa khatiso tsa 3D bakeng sa libaesekele, li-shock absorber, litiiso tsa rabara le li-insoles tsa lieta.

Likarolo tsa Sehlahisoa

| Branta | Tkapawell |

| Thepa | Polyurethane ea Thermoplastic ea boleng bo holimo |

| Bophara | 1.75mm/2.85mm/3.0mm |

| Boima bo kahare | 1 Kg/spool; 250g/spool; 500g/spool; 3kg/spool; 5kg/spool; 10kg/spool |

| Boima bo felletseng | 1.2Kg/spool |

| Mamello | ± 0.05mm |

| Lmoea | 1.75mm(1kg) = 330m |

| Tikoloho ea Polokelo | E omme ebile e na le moea o kenang |

| DSetulo sa ho lla | 65˚C bakeng sa lihora tse 8 |

| Lisebelisoa tsa tšehetso | Etsa kopo kaTOrwell HIPS, Torwell PVA |

| CTumello ea ho netefatsa | CE, MSDS, Reach, FDA, TUV le SGS |

| E lumellana le | Reprap,Ultimaker, End3, Creality3D, Raise3D, Prusa i3, Zortrax, XYZ Printing, Omni3D, Snapmaker, BIQU3D, BCN3D, Bambu Lab X1, AnkerMaker le liprinta life kapa life tse ling tsa FDM 3D |

| Sephutheloana | 1kg/spool; 8spools/ctn kapa 10spools/ctn mokotlana oa polasetiki o koetsoeng o nang le lintho tse nosetsang |

Thoto ea TPU ea Torwell e hlahella ka matla a eona a phahameng le ho tenyetseha, joalo ka motsoako oa polasetiki le rabara.

95A TPU e na le khanyetso e phahameng ea ho khohlela le khatello e tlase ha e bapisoa le likarolo tsa rabara, haholo-holo ha ho tlatsoa ho hoholo.

Ha ho bapisoa le likhoele tse tloaelehileng tse kang PLA le ABS, TPU e tlameha ho tsamaisoa butle haholo.

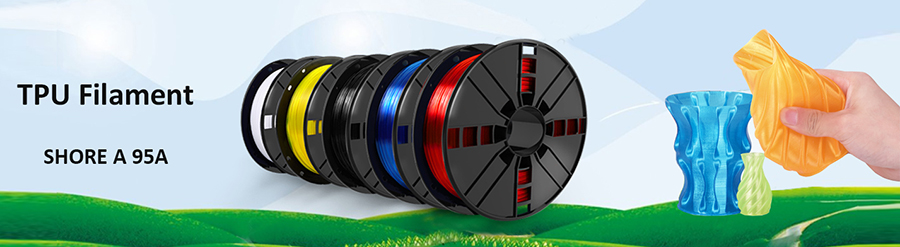

Mebala e Mengata

'Mala o fumanehang:

| 'Mala oa motheo | Bosweu, Botsho, Bofubedu, Boputsoa, Bosehla, Botala, Bohlooho, Lamunu, Bo bonaletsang |

| Amohela 'Mala oa PMS oa Moreki | |

Pontšo ea Mehlala

Torwell TPU Filament e feto-fetohang e lokela ho hatisoa ka lebelo le tlase ho feta le tloaelehileng. Le mofuta oa nozzle ea khatiso Direct Drive (motor e hoketsoeng nozzle) ka lebaka la mela ea eona e bonolo. Litšebeliso tsa filament tse feto-fetohang tsa Torwell TPU li kenyelletsa litiiso, lipolaka, li-gasket, lilakane, lieta, mokotla oa senotlolo bakeng sa setiiso sa rabara sa likarolo tsa baesekele tse tsamaeang tse kang shock le roale (Litšebeliso tsa Sesebelisoa se Aparoang/Ts'ireletso).

Sephutheloana

TPU ea 1kg ea roll 3D filament e nang le desiccant ka har'a sephutheloana sa vacuum.

Sekotlolo se seng le se seng ka lebokoseng le le leng (lebokose la Torwell, lebokose le sa nke lehlakore, kapa lebokose le ikhethileng lea fumaneha).

Mabokose a 8 ka lebokose (boholo ba lebokose ke 44x44x19cm).

Etsa bonnete ba hore filament ea hau ea TPU e bolokiloe sebakeng se omileng

Hlokomela hore TPU e na le hygroscopic, e bolelang hore e atisa ho monya metsi. Ka hona, e boloke e sa kene moea 'me e sirelelitsoe mongobo ka setshelong se koetsoeng kapa mokotlaneng o nang le sesebelisoa sa ho tlosa mongobo. Haeba filament ea hau ea TPU e koloba, u ka e omisa ka nako e ka bang hora e le 'ngoe mochesong oa 70°C ka ontong ea hau ea ho baka. Kamora moo, filament e omme 'me e ka sebetsoa joaloka e ncha.

Lisetifikeiti:

ROHS; REACH; SGS; MSDS; TUV

Tlhahisoleseling e Eketsehileng

Torwell FLEX e na le mesebetsi e mengata 'me e ka sebelisoa lits'ebetsong tse fapaneng tsa khatiso ea 3D, e leng se etsang hore e be khetho e phethahetseng bakeng sa mang kapa mang ea hlokang khoele e tenyetsehang e ka fihlelang litlhoko tsa hae tse ikhethang. Ebang u hatisa mehlala, li-prototype kapa lihlahisoa tsa ho qetela, u ka itšetleha ka Torwell FLEX ho fana ka likhatiso tsa boleng bo holimo tse lulang li fihlela kapa li feta litebello tsa hau.

Torwell FLEX ke khoele e ncha ea khatiso ea 3D e tla fetola tsela eo u nahanang ka likhoele tse tenyetsehang. Motsoako oa eona o ikhethang oa ho tšoarella, ho tenyetseha le bonolo ba tšebeliso o etsa hore e be e phethahetseng bakeng sa mefuta e fapaneng ea lits'ebetso ho tloha ho li-prosthetics le lisebelisoa tsa bongaka ho ea ho lisebelisoa tsa feshene. Joale hobaneng u ema? Qala ka Torwell FLEX kajeno 'me u natefeloe ke khatiso e ntle ka ho fetisisa ea 3D eo u ka e fanang!

Ho tšoarella ho Hoholo

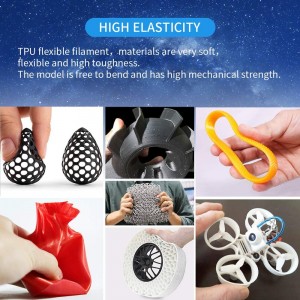

TkapawellTPU flexible filament ke thepa e bonolo le e tenyetsehang joalo ka rabara, e ts'oanang le Flexible TPE empa ho thaepa ho bonolo le ho feta TPE. E lumella motsamao o pheta-phetoang kapa ho otla ntle le ho petsoha.

Ho tenyetseha ho Hoholo

Thepa e tenyetsehang e na le thepa e bitsoang Shore hardness, e etsang qeto ea ho tenyetseha kapa ho thatafala ha thepa. Torwell TPU e na le Shore-A hardness ea 95'me e ka otlolla ka makhetlo a 3 ho feta bolelele ba eona ba pele.

| Botenya | 1.21 g/cm3 |

| Tekanyo ea Phallo ea Qhibilihang (g/10min) | 1.5()190℃/2.16kg) |

| Ho tiea ha lebōpo | 95A |

| Matla a tšepe | 32 MPa |

| Ho Lelefatsa Nako ea Phomolo | 800% |

| Matla a ho Tenyetseha | / |

| Modulus ea ho Flexural | / |

| Matla a Tšusumetso ea IZOD | / |

| Ho tšoarella | 9/10 |

| Ho ka hatisoa habonolo | 6/10 |

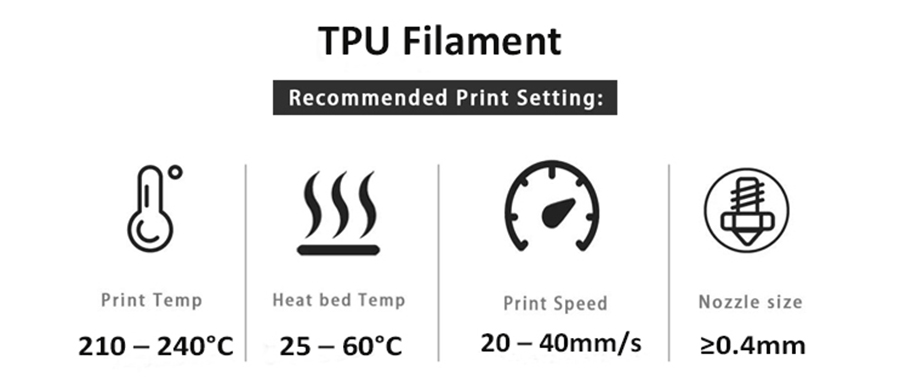

| Mocheso oa Extruder (℃) | 210 – 240℃ Khothaletso ea 235℃ |

| Mocheso oa bethe (℃) | 25 – 60°C |

| Boholo ba Nozzle | ≥0.4mm |

| Lebelo la Fene | Ka 100% |

| Lebelo la ho Hatisa | 20 – 40mm/s |

| Bethe e futhumetseng | Boikhethelo |

| Libaka tse Khothaletsoang tsa Kaho | Khalase e nang le sekhomaretsi, Pampiri ea ho phuthela, Theipi e Putsoa, BuilTak, PEI |

| Libaka tse Khothaletsoang tsa Kaho | Khalase e nang le sekhomaretsi, Pampiri ea ho phuthela, Theipi e Putsoa, BuilTak, PEI |

E kgothaletswa bakeng sa diprinta tse nang le direct drive extruder, di-nozzle tsa 0.4 ~ 0.8mm.

Ka Bowden extruder o kanna wa ela hloko malebela ana haholoanyane:

- Printa butle 20-40 mm/s Lebelo la ho printa

- Litlhophiso tsa lera la pele. (Bophahamo 100% Bophara 150% lebelo 50% mohlala)

- Ho hula morao ho timilwe. Sena se tla fokotsa sephetho sa khatiso se ferekantseng, se kgweleng kapa se ntšang metsi.

- Eketsa Katoloso (Ha ho hlokahale). Ho beha ho 1.1 ho tla thusa ho kopanya di-filament hantle. – Fene e phodileng e butswe kamora lera la pele.

Haeba o na le mathata a ho printa ka di-filament tse bonolo, pele, mme ha bohlokwa le ho feta, fokotsa lebelo la khatiso, ho e sebedisa ka lebelo la 20mm/s ho tla sebetsa hantle.

Ho bohlokoa ha o kenya filament ho e dumella hore e qale ho ntša feela. Hang ha o bona filament e tsoa nozzle, tobetsa konopo ea emisa. Tšobotsi ea ho kenya e sutumelletsa filament kapele ho feta khatiso e tloaelehileng 'me sena se ka etsa hore e tšoasoe ke gear ea extruder.

Hape fepa filament ka ho toba ho extruder, eseng ka tube ea feeder. Sena se fokotsa ho hula filament ho ka etsang hore gear e thelle holim'a filament.