Lifilamente tsa ho Hatisa TPU Plastiki e Tenyetsehang bakeng sa Printer ea 3D 1.75mm Lisebelisoa

Likarolo tsa Sehlahisoa

| Letšoao | Torwell |

| Thepa | Polyurethane ea Thermoplastic ea boleng bo holimo |

| Bophara | 1.75mm/2.85mm/3.0mm |

| Boima bo kahare | 1 Kg/spool; 250g/spool; 500g/spool; 3kg/spool; 5kg/spool; 10kg/spool |

| Boima bo felletseng | 1.2Kg/spool |

| Mamello | ± 0.05mm |

| Bolelele | 1.75mm(1kg) = 330m |

| Tikoloho ea Polokelo | E omme ebile e na le moea o kenang |

| Sebaka sa ho Omisa | 65˚C bakeng sa lihora tse 8 |

| Lisebelisoa tsa tšehetso | Sebelisa ka Torwell HIPS, Torwell PVA |

| Kamohelo ea Setifikeiti | CE, MSDS, Reach, FDA, TUV le SGS |

| E lumellana le | Makerbot, UP, Felix, Reprap, Ultimaker, End3, Creality3D, Raise3D, Prusa i3, Zortrax, XYZ Printing, Omni3D, Snapmaker, BIQU3D, BCN3D, MK3, AnkerMaker le liprinta life kapa life tse ling tsa FDM 3D |

| Sephutheloana | 1kg/spool; 8spools/ctn kapa 10spools/ctn mokotlana oa polasetiki o koetsoeng o nang le lintho tse nosetsang |

Mebala e Mengata

'Mala o Fumanehang:

| 'Mala oa motheo | Bosweu, Botsho, Bofubedu, Boputsoa, Bosehla, Botala, Bohlooho, Lamunu, Bo bonaletsang |

| Amohela 'Mala oa PMS oa Moreki | |

Pontšo ea Mehlala

Sephutheloana

Rola 1kg ea TPU filament e nang le desiccant ka har'a sephutheloana sa vaccum.

Sekotlolo se seng le se seng ka lebokoseng le le leng (Lebokose la Torwell, Lebokose le sa nke lehlakore, kapa Lebokose le ikhethileng le ka fumaneha).

Mabokose a 8 ka lebokose (boholo ba lebokose ke 44x44x19cm).

Setsi sa Feme

Tlhahisoleseling e Eketsehileng

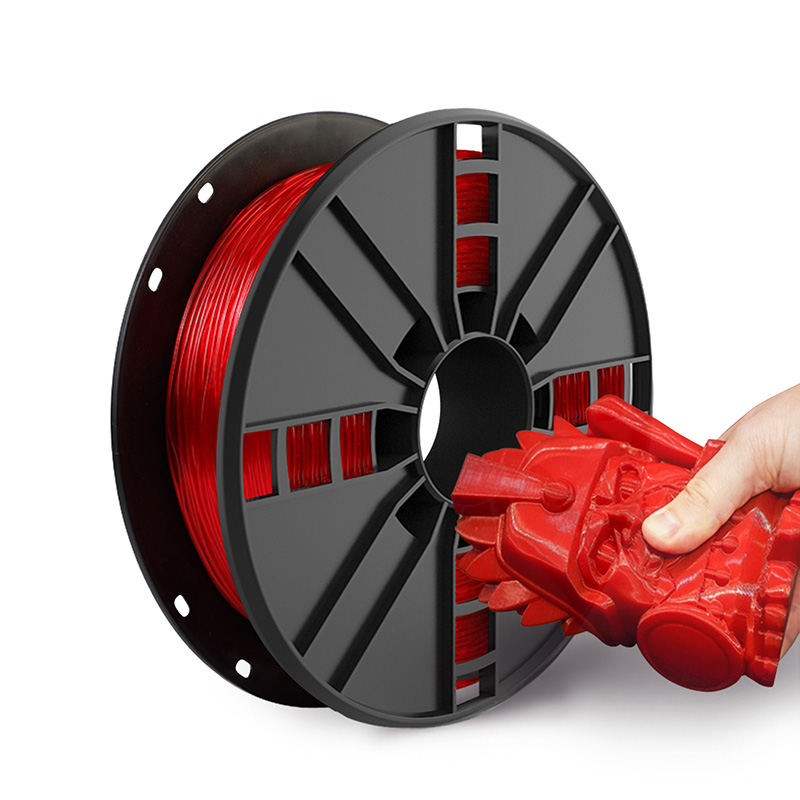

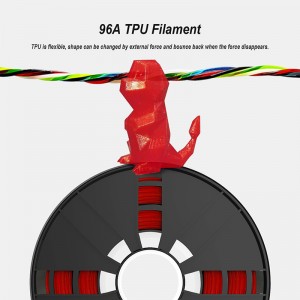

Ho hlahisa Torwell FLEX, filament ea morao-rao ea TPU e etselitsoeng thepa e bonolo ea khatiso ea 3D. Filament ena e ncha e entsoe ka polyurethane ea thermoplastic, polymer e feto-fetohang haholo le e sebelisoang hangata, e etselitsoeng ka ho khetheha ho u fa phihlelo e ikhethang ea 3D.

E 'ngoe ea litšobotsi tse hlahelletseng tsa Torwell FLEX ke ho tšoarella ha eona ho tsotehang. Khoele ena e lekiloe ka botlalo 'me e hanela ho hohloka, ho taboha le ho hohloka ho etsang hore e be ntle bakeng sa lits'ebetso tse nang le khatello e phahameng moo ho seng joalo khoele e tenyetsehang e neng e tla hloleha. Ho feta moo, ho tenyetseha ha eona le matla a eona li etsa hore e be ntle bakeng sa ho etsa lintho tse hlokang ho tenyetseha ho itseng, joalo ka lisebelisoa tsa bongaka, li-prosthetics, kapa lisebelisoa tsa feshene.

E 'ngoe ea litšobotsi tse ikhethang tsa Torwell FLEX ke bonolo ba eona ba ho e sebelisa. E etselitsoe ka ho khetheha bakeng sa ho hatisa habonolo, ka bophara bo lekanang haholo le ho fokotseha ho tlase, e fokotsang monyetla oa ho sotha le ho netefatsa boleng bo botle ba khatiso. Ho feta moo, litšobotsi tsa eona tse tsitsitseng haholo tsa khatiso li etsa hore e be khetho e ntle bakeng sa ba qalang le ba nang le boiphihlelo ba khatiso ea 3D.

Hore na o sa tsoa qala ho hatisa ka 3D kapa o setsebi se nang le boiphihlelo, Torwell FLEX e ka thusa. Likarolo tsa eona tse ikhethang li fana ka melemo e mengata e e khethollang ho thepa ea khatiso ea 3D e tloaelehileng, e leng se etsang hore e be khetho ea pele bakeng sa mefuta e fapaneng ea lits'ebetso tsa khatiso ea 3D tse tenyetsehang.

Ke hobane'ng ha bareki ba bangata hakaale ba khetha TORWELL?

Mofani oa rona oa likhoele o fana ka leseli linaheng tse ngata lefatšeng.

Melemo ea filament ea Torwell:

Boleng

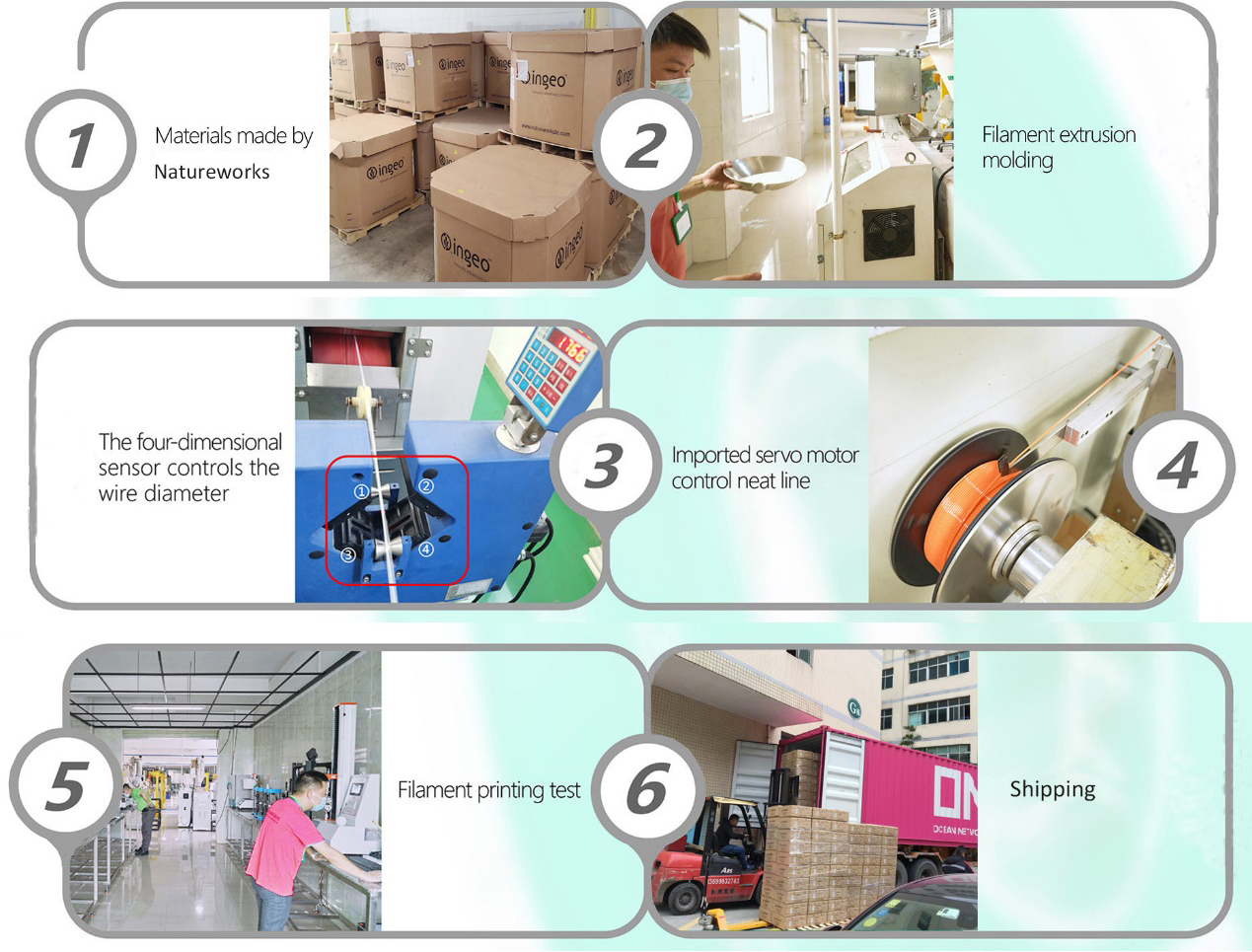

Boleng ke botumo ba rona, re na le mehato e robeli bakeng sa tlhahlobo ea rona ea boleng, Ho tloha thepa ho ea thepa e felileng. Boleng ke seo re se phehellang.

Tšebeletso

Moenjiniere oa rona o tla ba teng tšebeletsong ea hau. Re ka u fa tšehetso ea theknoloji neng kapa neng.

Re tla be re latela liodara tsa hau, ho tloha pele ho thekiso ho isa kamora thekiso 'me re tla boela re u sebeletse ts'ebetsong ena.

Theko

Thekiso ea fektheri ka kotloloho, e nang le theko e qothisanang lehlokoa. 'Me theko ea rona e ipapisitse le bongata, Ho feta moo, matla a mahala le fene li tla u romella. Sampole ea mahala e fanoe.

Khetha TORWELL, u khetha e theko e tlaase, ea boleng bo holimo le tšebeletso e ntle.

| Botenya | 1.21 g/cm3 |

| Tekanyo ea Phallo ea Qhibilihang (g/10min) | 1.5 (190℃/2.16kg) |

| Ho tiea ha lebōpo | 95A |

| Matla a tšepe | 32 MPa |

| Ho Lelefatsa Nako ea Phomolo | 800% |

| Matla a ho Tenyetseha | / |

| Modulus ea ho Flexural | / |

| Matla a Tšusumetso ea IZOD | / |

| Ho tšoarella | 9/10 |

| Ho ka hatisoa habonolo | 6/10 |

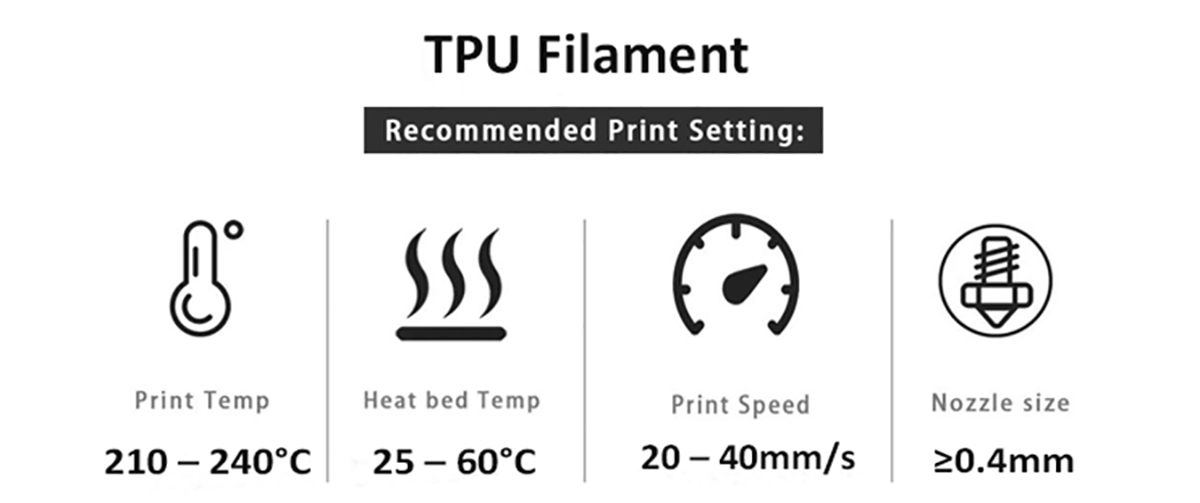

| Mocheso oa Extruder (℃) | 210 – 240℃ E khothaletsoa 235℃ |

| Mocheso oa bethe (℃) | 25 – 60°C |

| Boholo ba Nozzle | ≥0.4mm |

| Lebelo la Fene | Ka 100% |

| Lebelo la ho Hatisa | 20 – 40mm/s |

| Bethe e futhumetseng | Boikhethelo |

| Libaka tse Khothaletsoang tsa Kaho | Khalase e nang le sekhomaretsi, Pampiri ea ho phuthela, Theipi e Putsoa, BuilTak, PEI |